Encouraged To Rethink the conventional

A Revolution in Bulk Material Handling

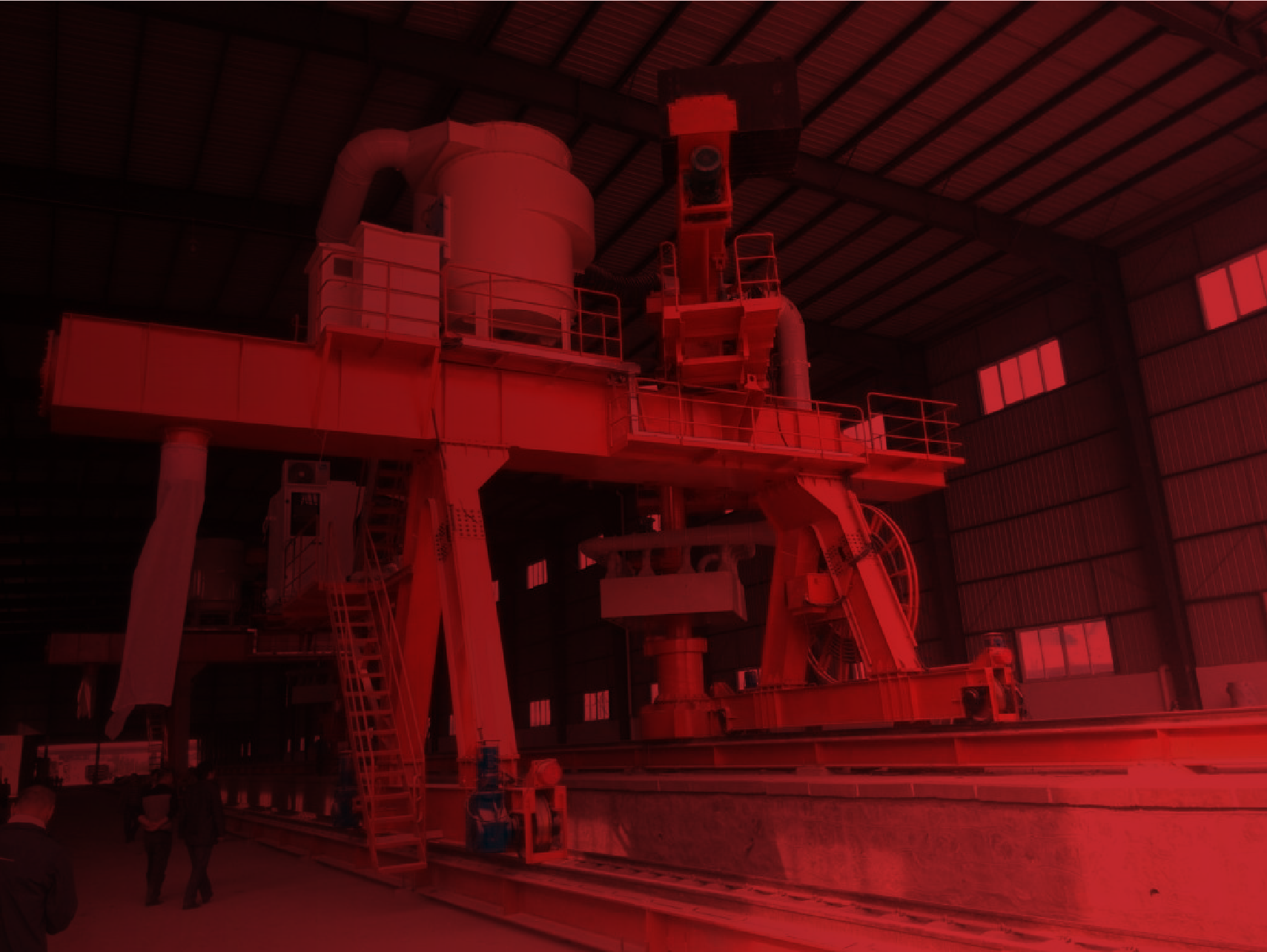

Our Enclosed Type Vertical Spiral Unloading Machine is a high-tech product designed to efficiently and safely handle bulk materials such as coal, grain, chemical fertilizer, gasohol derived from cassava, mineral powder and cement. Developed through decades of research, this machine is protected by multiple patents and represents a significant advancement in bulk material unloading technology.

Applications

Our enclosed vertical spiral unloading machine is ideal for:

Railway bulk material unloading

Handling various bulk materials including coal, grain, chemical fertilizers and more

Key Features

Single-set unloading efficiency can reach up to 550m³/h

Minimal material residual of approximately 1 ton, with optional warehouse clearance devices

Capable of forming multiple-set working teams to achieve kiloton-level efficiency for large goods yards

Fully enclosed material circulation process minimizes dust pollution

Optional dedicated dust removal equipment ensures a clean working environment

Direct discharge to belt conveyor, goods van, or goods yard with minimal dust pollution

Equipped with frequency control for lower energy consumption

Maximum output power of 221 kW

Safe and comfortable driving cab with broad vision and intelligent operation

Autonomic deviation rectification during curve traveling and double-limiting stopper to prevent collisions

Balanced center of gravity for wind resistance up to Level 8

Can utilize tracks from original chain bucket type and horizontal spiral unloading machines without new foundations

- High Efficiency and Speed

- Environmental Protection

- Energy Saving

- Safety and Convenience

By choosing our enclosed vertical spiral unloading machine, you are investing in advanced technology that ensures high efficiency, environmental protection, energy savings, and safety in your bulk material handling operations.